A Brief Overview of Gravure Printing

Gravure printing is a high-quality printing process, also known as rotogravure printing, that is widely used in the packaging, textile, and publishing industries. The term “gravure” is derived from the French word “graver,” which means “to engrave.”

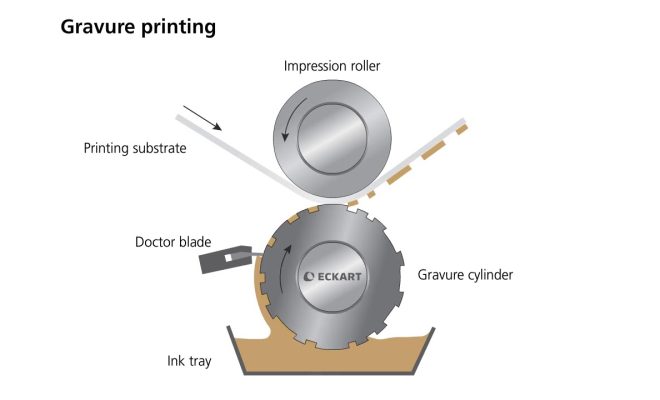

The process of gravure printing involves engraving an image or design onto a cylinder. The cylinder is then coated with ink, and the ink is transferred onto the substrate, such as paper or plastic. Gravure printing has a unique advantage over other printing processes, as it can produce high-quality images with sharp and clear details.

The gravure printing process starts with the preparation of a cylinder, which is typically made of copper or steel. The cylinder is then coated with a photosensitive emulsion, which is selectively exposed to light through a positive image. The areas that are exposed to light become hardened, while the unexposed areas remain soft.

The next step is the engraving process, where the unexposed areas are etched away from the cylinder, creating recessed wells or cells. The depth and shape of the cells determine the amount and distribution of the ink that will be transferred onto the substrate during printing.

Once the cylinder is engraved, it is mounted onto a printing press. The press has a series of rollers that apply ink onto the cylinder and then transfer the ink onto the substrate. The pressure applied by the press forces the ink out of the cells and onto the substrate, creating a clear, sharp image.

Gravure printing is particularly suited for printing high volumes of packaging materials such as bags, pouches, and labels, as well as publishing materials such as magazines, catalogs and coffee table books. Gravure printing can also print high-quality images on flexible packaging materials, especially when combined with other printing technologies such as flexography and digital printing.

In conclusion, gravure printing is an intricate and high-quality printing process that produces durable and high-quality images with exceptionally sharp details. This printing process is particularly suited for printing high volumes of packaging materials and publishing materials, making it a popular choice for companies in these industries. As technology continues to evolve, gravure printing will continue to play a critical role in the printing industry.